The Story of Carpenters' Hall

Interview of Nicholas A. Gianopulos, Structural engineer and Company member since 1976

by Carl G. Karsch

Model of the construction of the Hall

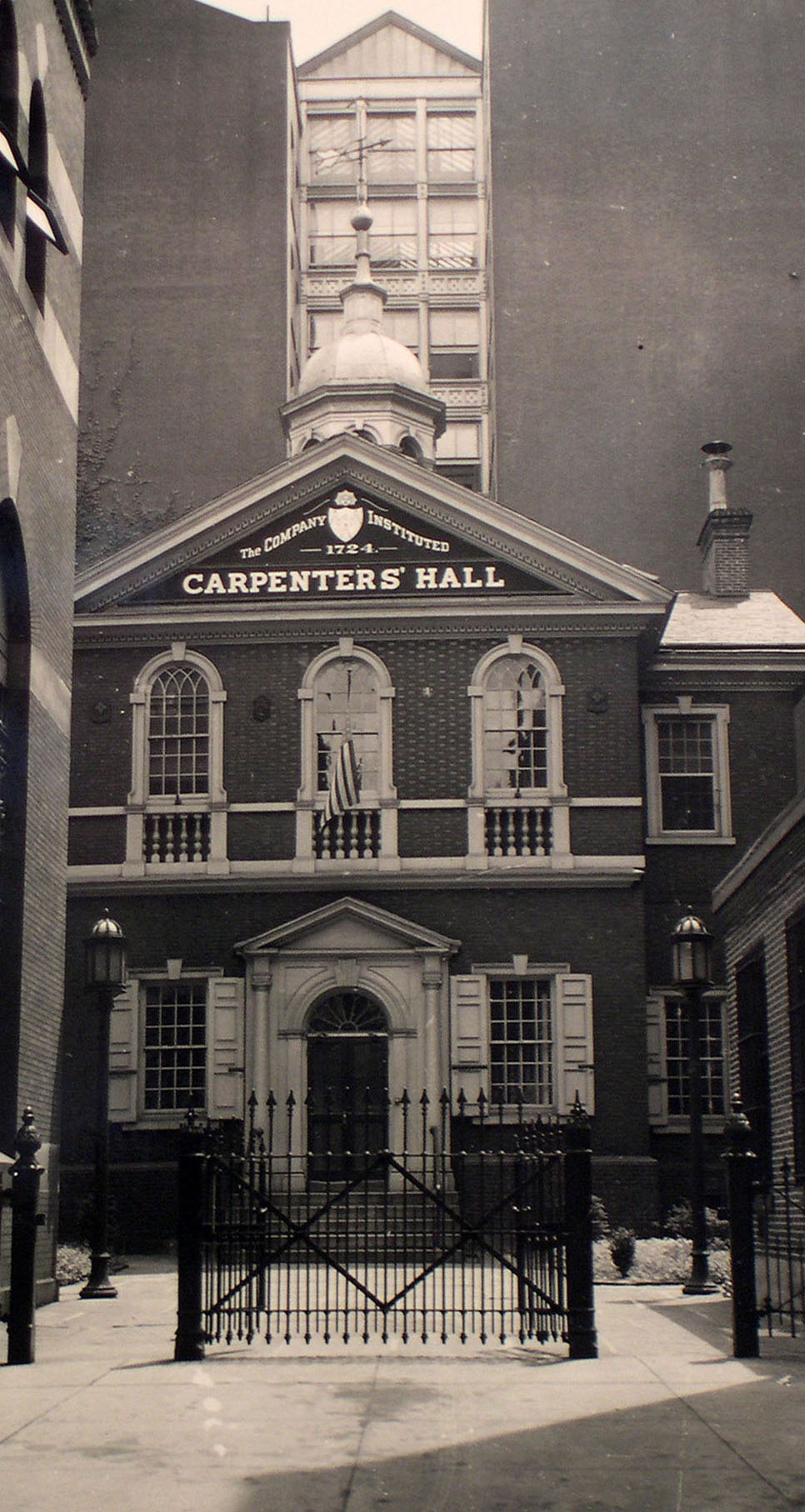

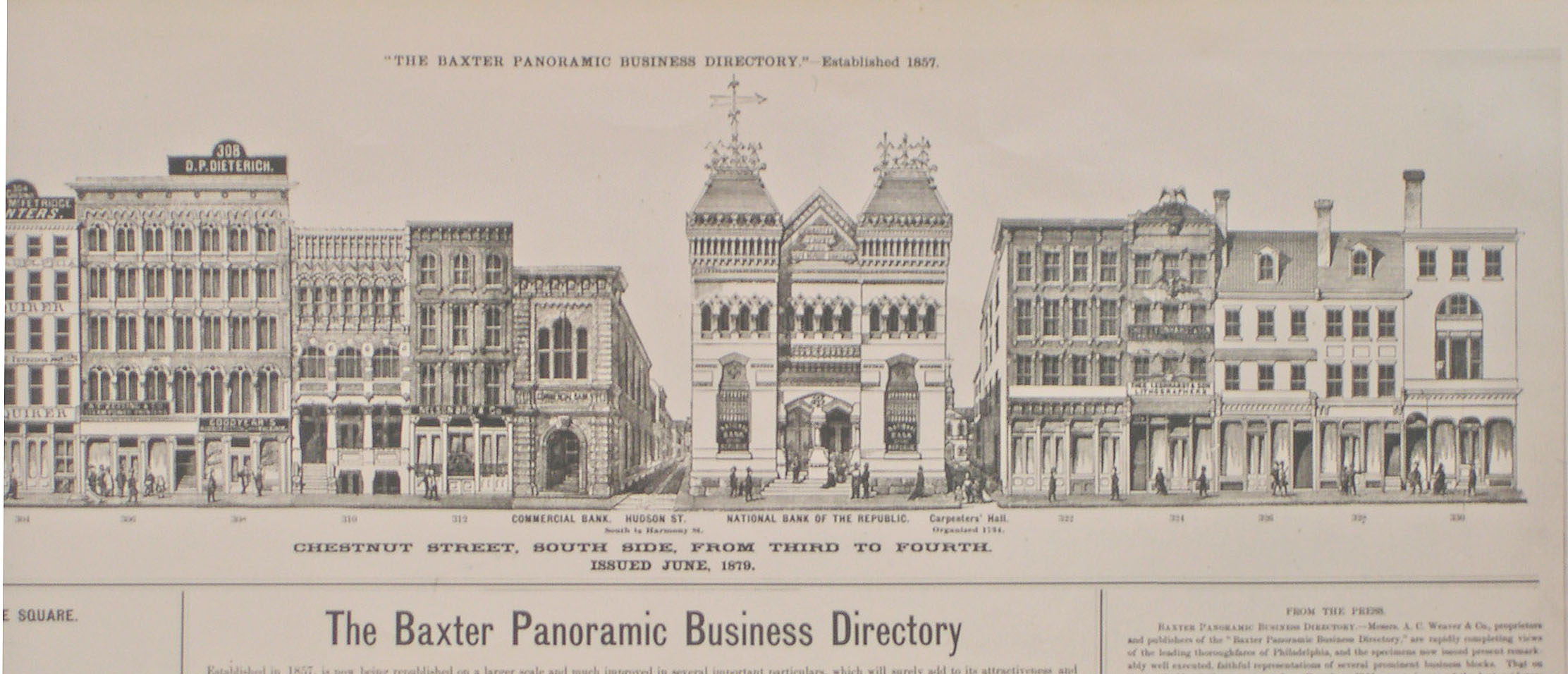

On New Year's Day, 1770, Carpenters' Company members voted to proceed with their Hall. More than a meeting place, the Hall would showcase their considerable technical skills and also be available for rent. For many years the Hall was the largest rental space in the city. This fact alone assured Carpenters' Hall a key role in the events of the War for Independence.

Robert Smith, a Scottish-trained architect and builder, headed a 12-man construction committee. Smith, then 48, had a well-established reputation not only in Philadelphia but throughout the colonies. It is a tribute to Smith that his colleagues in the Company charged him with the design. Unfortunately Carpenters' Hall was among his last achievements. In the winter of 1777, he died while helping construct fortifications, which prevented the British fleet from capturing the city.

Smith's plan was simplicity itself: a two-story, 50-foot square building with 10-foot cutouts at each corner. The result is a gem of Georgian-style architecture, which is both a fitting memorial to Smith and a tribute to the builders. The square-ness and accuracy of its construction is equal to that of contemporary structures.

Robert Smith's Floorplan

Interior steel supports modern structures. Not so in the 18th century. The weight of Carpenters' Hall is principally borne by the exterior brick walls, which are 13 inches thick. The black-colored bricks, called "headers," are turned on end and tie together several courses of bricks which otherwise might separate at the mortar joints. The foundation is equally sturdy, consisting of random-sized pieces of stone mortared together in what is known as a "rubble foundation."

Power tools were non-existent. Picks and shovels plus workmen's back-breaking labor built the basement. Supporting the first floor are two girders, each 45 feet long and roughly squared off with an adze. No sawmill was large enough to handle them. These girders and most of the building's other timber framing were of Eastern White Pine, which is hardly available today. To provide maximum support, the timbers were reversed; that is, the base of one is at the basement's west end and the stump end of its mate lies at the east. As a result, carpenters had to custom-fit each joist to the taper of the timbers. Joists are parallel timber beams used to support the floor and ceiling loads, supported, in turn by larger beams, girders, or bearing walls. Apprentices performed the labor-intensive joinery, under the direction of a master carpenter. Mortise and tenon joints connecting joists to the timbers had to fit exactly. And they still do.

Visitors often question whether the tile on the first floor is "original." The answer: it was installed after the Civil War as crowds of visitors grew. Ironically, a British company named Minton supplied the tile both for Carpenters' Hall and for another famous building, the United States Capitol. But The Carpenters' Company, mindful of their thrifty Quaker forebears, sawed the original yellow pine flooring into short lengths needed to support mortar beds for the tile. The short lengths of the early wood flooring that were installed between the floor joists can be seen from the basement below.

One of Benjamin Franklin's recommendations for fireproofing is incorporated into the second floor. Beneath the floor boards, between the joists, are strips of wood lath heavily coated with plaster, an excellent material for retarding the spread of fire in a building. A finished ceiling of wood lath and plaster was constructed on the bottoms of the second floor joists. Another benefit of the plaster work beneath the floor boards, was that of reduced noise transmission through the second floor construction.

Queen Post Truss

Now for some 18th-century structural engineering. To make possible a 50-foot building with no interfering supports in the basement and first floor — as in Carpenters' Hall — required special trusses. Within the partitions on the second floor are two trusses spanning the building's north-south axis. Because of the placement of the trusses' vertical timbers, engineers (by a flight of Freudian fancy) term them "queen post trusses." Overhead in the attic is a "king post truss" supporting the cupola and roof trusses. The 30-foot roof trusses on the north-south axis also have additional strengthening. Timbers forming the trusses were meticulously fitted with mortise and tenon joints, then secured with heavy wooden pegs, the principal means of fastening large pieces of lumber during that period. Wrought-iron hardware was available for special joint connections where conditions so required.

Ever hear of dendrochronology? If not, don't be embarrassed. It's a means of dating buildings or historical events by studying tree rings. Here's how it works. Annual growth rings of trees vary accordingly to rainfall and growing conditions. By removing small samples of wood from buildings in a particular region with overlapping dates of construction, it is possible to construct a continuous accurately dated "time line" of growth rings. Wood samples from buildings about which little is known are then matched against the "time line" to determine when they were constructed. Samples from roof trusses in Carpenters' Hall are part of Philadelphia's dendrochronology timeline.

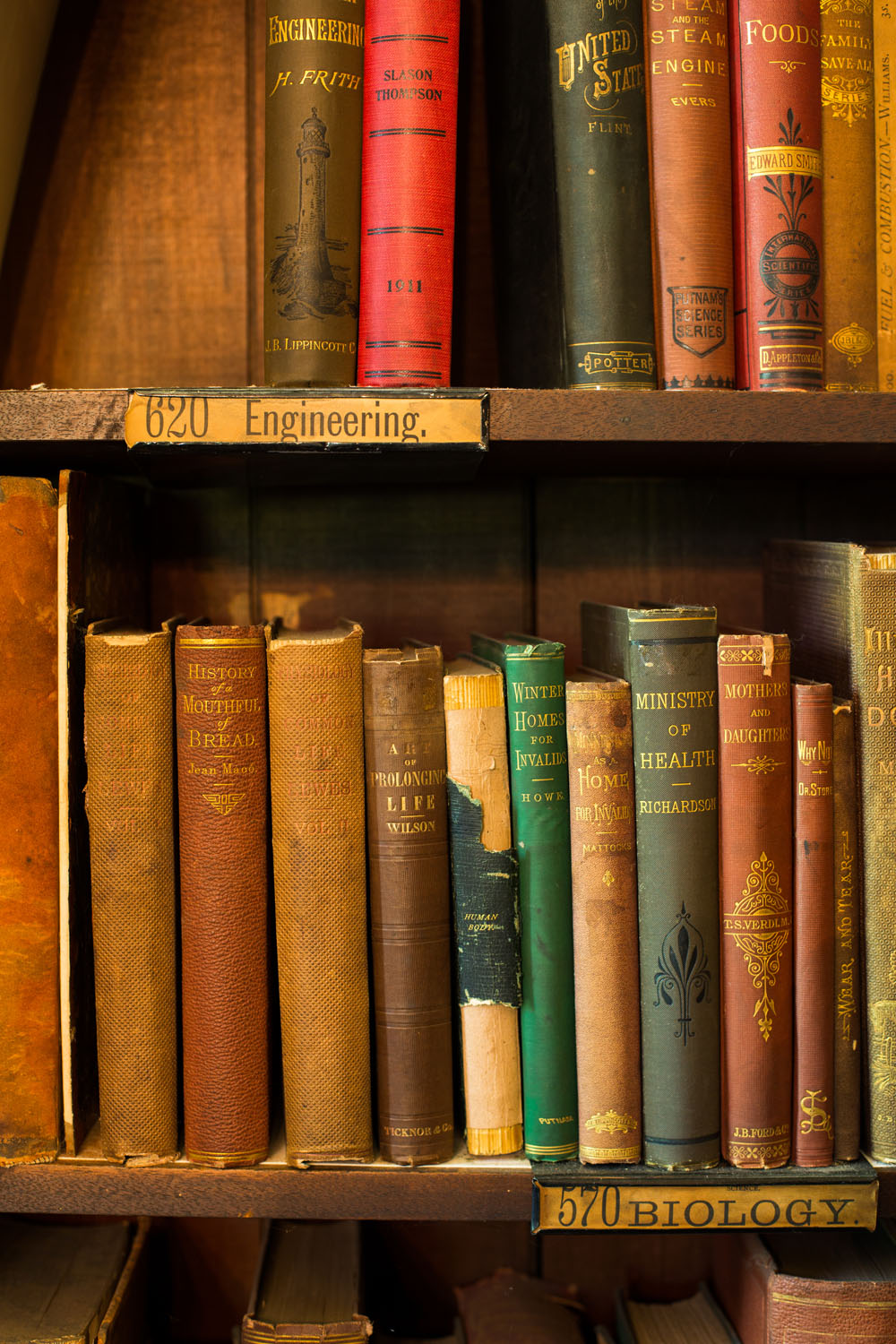

The roof of Carpenters' Hall looks like wood shingles, the original covering, but in reality is fireproof, ceramic tile. Sounds like a good idea, but it helped create an expensive problem. The original cedar shingles lasted, with some repairs, for 75 years. In the 1850s shingles were replaced by slate. Instead of furring strips, the slate required solid board sheathing. A century later ceramic tiles replaced the slate. With each change, the roof load increased — from 3 to 4 pounds per square foot with shingles, to 12 pounds for slate, to 15 pounds for tile. It's hardly surprising this greatly increased roof load was too much for the "king post truss," which sagged onto the second floor "queen post trusses." Making matters worse was the Company's library housed in the west room. Full height bookcases, loaded with volumes on architecture and related subjects were installed in the 1850s, loading an extra 18,000 pounds onto the west "queen post truss." An inspection in the 1970s revealed dangerous stress cracks in some joints of the trusses.

A network of steel rods and steel beams in the attic now transfers the loads of both the roof and the second floor from the trusses on the four interior corners of the building. Equally important, the function of the original structure is preserved, but now serving to collect and transfer loads to the new steel framing. The designer, Nicholas A. Gianopulos, is a Company member and structural engineer who has come to the rescue of more than one historic building in Philadelphia.

Thanks to modern engineering and a company which cherishes its unique building, Carpenters' Hall is ready for the 21st century.